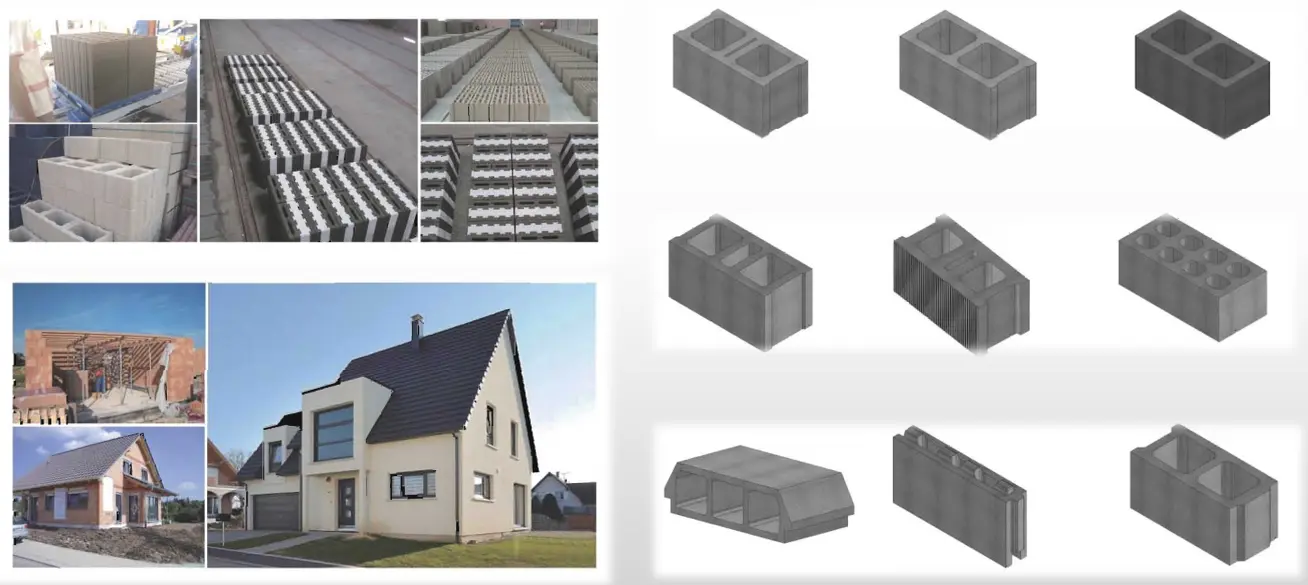

QGM Block Machine as the professional manufacturer, we would like to provide you high quality Block Mold. And we will offer you the best after-sale service and timely delivery.

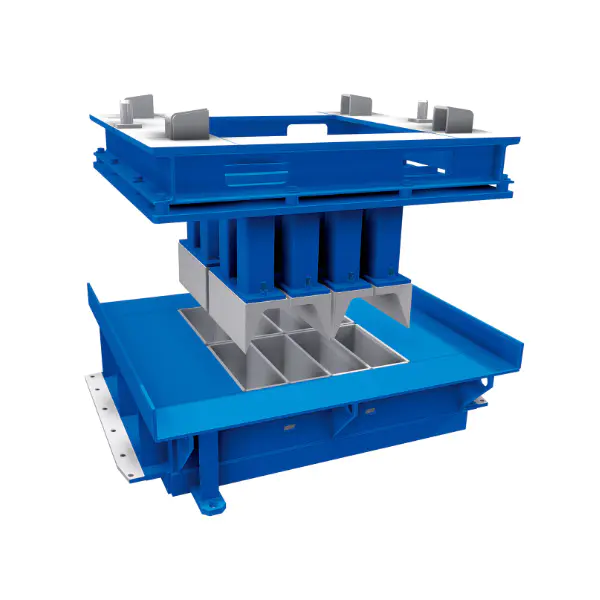

Block mold is also called grass brick mold, color brick mold and other series. The mold steel is made of high-quality alloy steel, with advanced processing technology and high precision. Block machine mold users need to customize the design. The block machine mold is shock-resistant, wear-resistant, and the finished product size is accurate. The block machine mold occupies a very important position in the entire brick machine equipment. The appearance, quality and production efficiency of the products produced play a decisive role in the entire set of equipment.

The precautions for block machine molds are as follows:

1. When installing or replacing new or old molds, be sure to avoid collisions and bumps, civilized assembly, and pay attention to protecting the mold.

2. During use, frequently check the mold size and the condition of the welding joints. If weld cracks appear, they should be repaired in time. If the wear is too fast, the aggregate particle size should be adjusted. If the wear affects the quality of the product, a new mold needs to be equipped.

3. Carefully adjust the gap, including the spacing between the pressure head and the mold core, the pressure head and the material car movement plane, the mold frame and the line plate, etc. Relative movement must not interfere or collide.

4. When cleaning the mold daily, use an air compressor and soft tools to remove concrete residues. It is strictly forbidden to knock or pry the mold with gravity.

5. The replaced block machine mold should be cleaned, oiled to prevent rust, and placed flat on a dry and flat place to prevent gravity deformation.