Paver moulds play a critical role in the production of high-quality paving stones. With advancements in manufacturing technology, modern paver moulds offer superior durability, precision, and customization options. Whether for industrial or commercial applications, selecting the right mould is essential for achieving optimal results in stone production.

A well-designed paver mould ensures precise shaping, smooth surfaces, and long-term durability. Here are the key features that define a high-quality paver mould:

1. High-Strength Case-Hardened Steel

The durability of a paver mould depends on the material used. High-strength case-hardened steel enhances resistance to wear and ensures a longer service life, even under intensive use.

2. Advanced Wire-Cutting and CNC Machining

Precision in paver mould manufacturing is achieved through a wire-cutting process and CNC machining. These technologies allow for intricate designs and maintain uniform quality in every mould produced.

3. Custom 3D Scanning Technology

The ability to customize paver moulds with 3D scanning technology ensures that customers can create unique contours and geometries. This level of customization provides flexibility for different paving stone designs.

4. High-Precision and Smooth Finishing

With a clearance of 0.3-0.4 mm, modern paver moulds offer precise vertical angles and smooth sidewalls. This eliminates burrs on the final stone products, ensuring clean and accurate shapes.

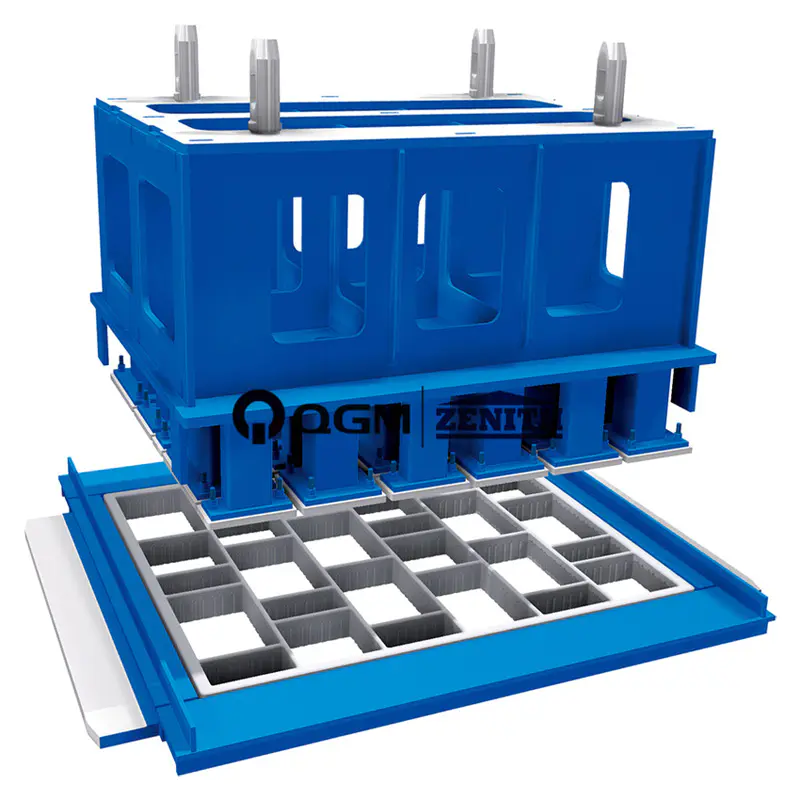

5. Interchangeable Pressure Plate Design

The free surface digital design and interchangeable pressure plates enhance flexibility in stone production. This allows manufacturers to adjust designs without replacing entire moulds, optimizing efficiency and cost-effectiveness.

To achieve long-lasting performance, paver moulds undergo specialized hardening treatments:

- Hardness of 60-63HRC: This hardness level provides excellent resistance to deformation and wear, ensuring that the mould maintains its precision over time.

- Hardening Depth of 1.2mm: The deep hardening process enhances durability, allowing the mould to withstand high pressure and repeated use.

- Custom Manufacturing Options: Depending on customer needs, the mould can be designed and manufactured using welding or blocking modular threads for increased strength and adaptability.

The accuracy of a paver mould directly impacts the quality of the paving stones produced. A mould with precise vertical angles and a smooth surface ensures:

- Consistent stone dimensions for uniform installation

- A flawless finish without sharp edges or irregularities

- Reduced material waste and higher production efficiency

Choosing the right paver mould is essential for high-quality stone production. With advanced steel materials, CNC machining, and customizable 3D scanning, manufacturers can achieve precise and durable moulds tailored to their needs. Investing in a well-engineered paver mould not only enhances production efficiency but also guarantees superior results in paving stone manufacturing.

QGM Mould Co., Ltd. is one of the wholly-owned subsidiaries of Quangong Machinery Co., Ltd. It concentrates on the design, production, sales, and maintenance of molds for block-making machines. QGM has member enterprises like ZENITH in Germany, ZENITH Mold in Austria, and a joint venture called Apollo Zenith in India. Explore our full range of products on our website at https://www.qgmmould.com/. For any inquiries, please reach out to us at zengxm@qzmachine.com.