Curbstone moulds play a critical role in modern construction, ensuring the production of durable and precisely shaped curbstones for roads, sidewalks, and landscaping projects. A high-quality curbstone mould, designed with advanced materials and manufacturing techniques, enhances efficiency, longevity, and flexibility. But what makes a well-engineered mould essential for producing superior curbstones?

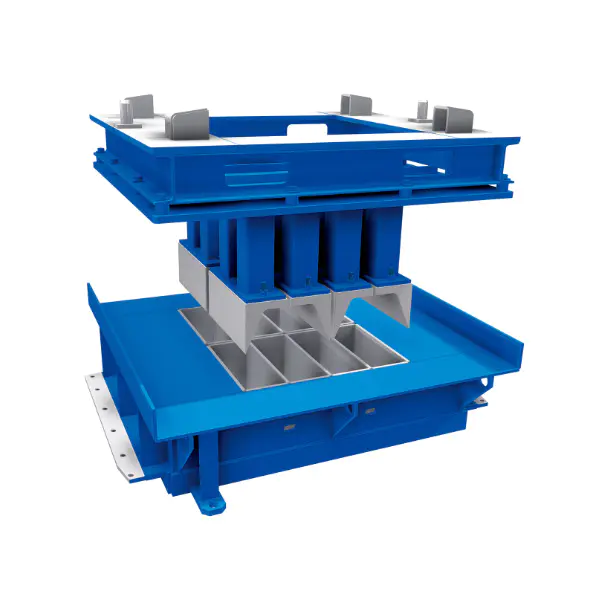

A premium curbstone mould is crafted using imported wear-resistant steel, offering exceptional durability and resistance to deformation. The combination of CNC machining and precision welding ensures structural integrity and accurate curbstone formation. Additionally, a heat treatment process with a hardness level of 58-62HRC enhances wear resistance, allowing the mould to withstand high-pressure usage over time.

Modern curbstone moulds incorporate hydraulic devices, allowing the frame plate to be folded as needed. This feature enhances operational flexibility and simplifies the replacement of worn parts, minimizing downtime and reducing maintenance costs.

Advantages of a hydraulic-equipped curbstone mould include:

- Easy disassembly and maintenance for efficient part replacement

- Greater flexibility to accommodate different curbstone designs

- Enhanced production efficiency by reducing manual adjustments

Curbstone moulds can be customized to meet specific project requirements. Manufacturers offer variations such as:

- Beveled or straight-edged designs

- Moulds with or without face mix

- Replaceable plates for adjusting curbstone height and bevel

This level of customization allows construction companies to produce curbstones that meet aesthetic and functional demands without requiring entirely new moulds.

These moulds are widely used in:

- Road and highway construction for durable curbstone production

- Urban landscaping for aesthetic and functional boundary solutions

- Sidewalk and pavement projects to ensure uniformity and precision

- Infrastructure development requiring large-scale curbstone manufacturing

A high-quality curbstone mould is an indispensable tool for construction professionals seeking precision, durability, and efficiency. With advanced materials, heat treatment, and hydraulic adaptability, these moulds provide a reliable solution for manufacturing robust curbstones that meet industry standards. Customization options further enhance flexibility, making them ideal for a wide range of projects.

QGM Mould Co., Ltd. is one of the wholly-owned subsidiaries of Quangong Machinery Co., Ltd (QGM). It concentrates on the design, production, sales, and maintenance of molds for block-making machines. QGM has its member enterprises like ZENITH in Germany, ZENITH Mold in Austria, and a joint venture called Apollo Zenith in India. Explore our full range of products on our website at https://www.qgmmould.com/. For any inquiries, please reach out to us at zengxm@qzmachine.com.