In the global construction industry, the quality and consistency of building materials directly affect the durability and appearance of every project. For international buyers seeking reliable production tools, the brick making machine steel mold stands out as a critical asset. It plays a vital role in shaping bricks with accuracy, efficiency, and long-term reliability.

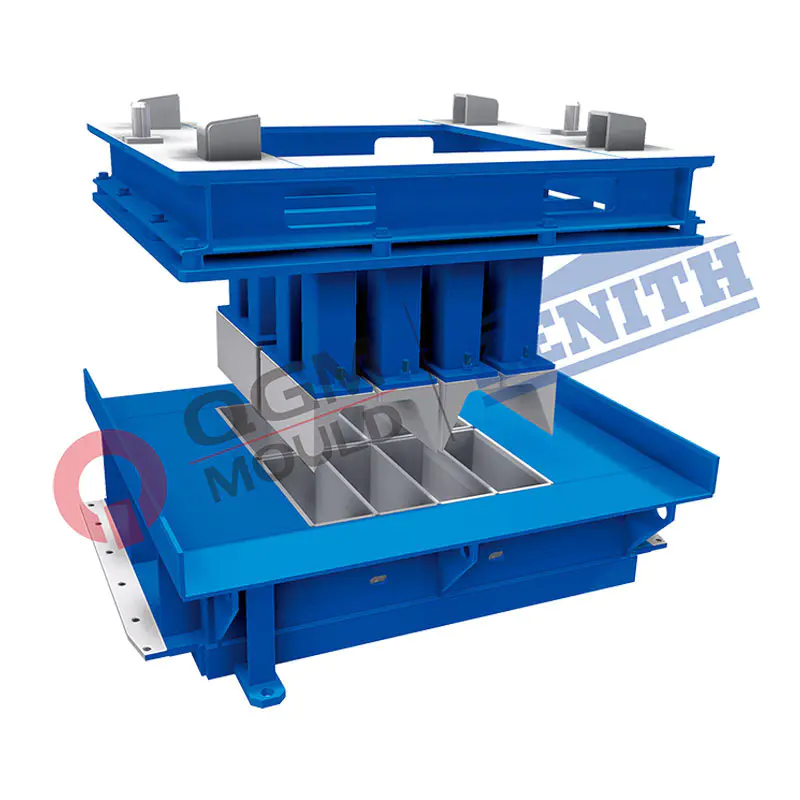

A steel mold for a brick making machine is a high-precision tool designed to produce various types of concrete bricks. Whether you’re manufacturing standard bricks, hollow blocks, curbstones, Dutch bricks, grass pavers, or large square bricks, these molds are built to handle the task.

Manufactured from alloy steel and strengthened with heat treatment, these molds are engineered to resist wear and maintain performance even under high production demands. They ensure that every brick is uniform in size, smooth in finish, and strong in structure.

Choosing a top-quality steel mold for your brick making machinery can enhance your production in several key ways:

1. Longer Service Life: Heat-treated alloy steel resists wear and deformation, reducing the need for frequent replacements.

2. Consistent Quality Output: Precision-made molds deliver bricks with clean edges and accurate dimensions, ensuring each product meets industry standards.

3. Increased Efficiency: Faster demolding and stable shaping help speed up production and minimize material waste.

4. Tailored Designs: Molds can be customized to match local construction standards or specific project requirements, offering you more flexibility in product lines.

5. Reduced Maintenance Costs: Easy-to-replace parts and robust construction make routine maintenance simpler and less costly.

These steel molds are widely used in various sectors, including:

· Residential and commercial developments

· Landscaping and public spaces (e.g., curbstones, pavers)

· Roadwork and urban infrastructure

· Retaining walls and drainage systems

Their versatility makes them a go-to solution for construction companies around the world aiming for both performance and cost-effectiveness.

QGM Mould Co., Ltd. is a trusted name in the global market. As a wholly-owned subsidiary of Quangong Machinery Co., Ltd (QGM), we specialize in the design, production, sales, and support of high-performance molds for brick- and block-making machines.

Our group includes internationally respected brands such as ZENITH (Germany), ZENITH Mold (Austria), and Apollo Zenith (India)—enabling us to offer global standards with localized service. We support our international customers with turnkey solutions that prioritize performance, customization, and long-term value.

Explore our full range at https://www.qgmmould.com/

For inquiries or custom requirements, contact us at zengxm@qzmachine.com.