QGM Block Machine is a reputable Chinese manufacturer and supplier with years of experience specializing in Unburned Brick Machine Mold production. We hope to establish commercial ties with you.

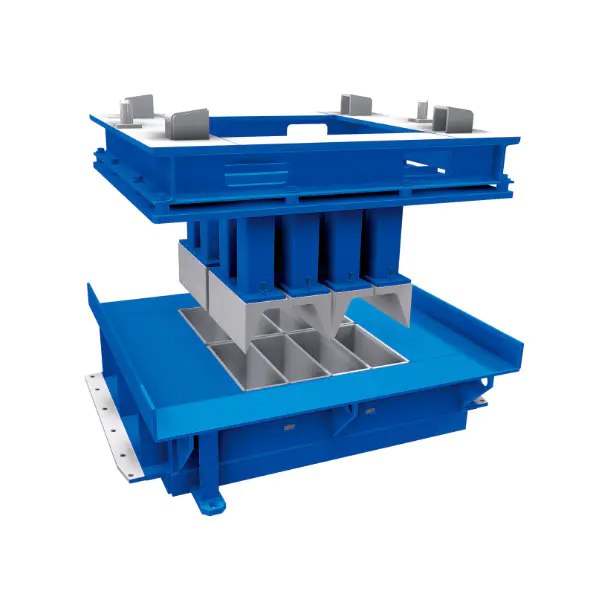

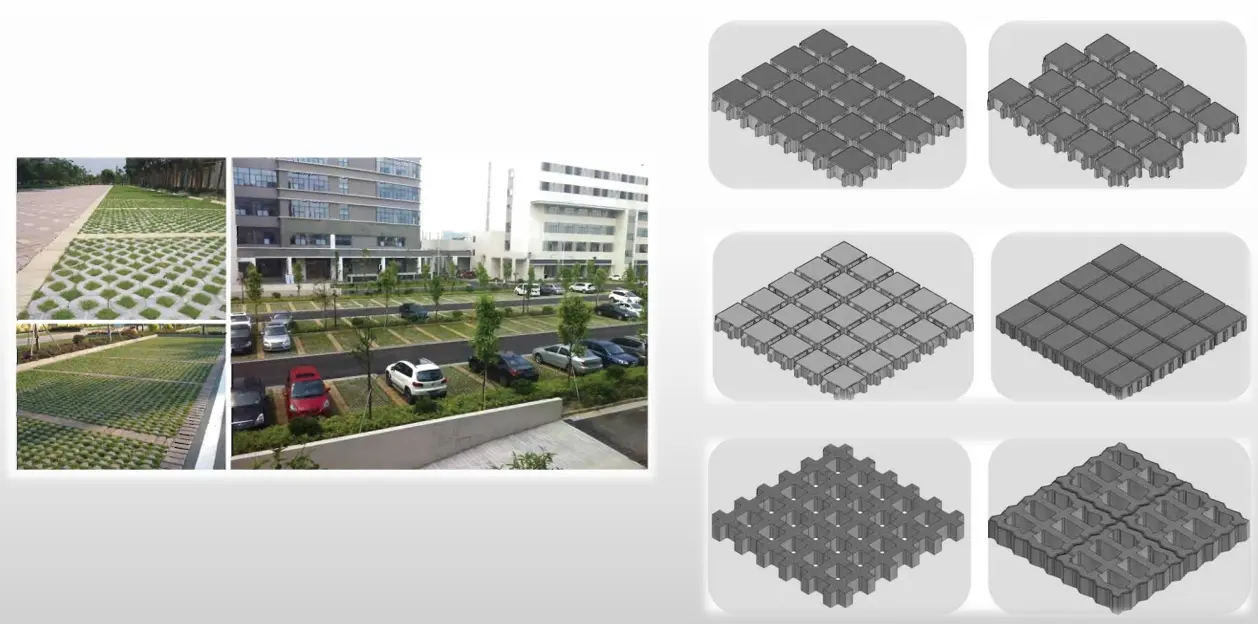

Unburned brick machine mold is a key component specially used in unburned brick machine production equipment. Unburned brick machine mold, as the core tool of brick machine series machinery, is customized according to the brick size and specifications required by the user. In industrial production, this mold is used to obtain brick products of the required shape by injection molding, die casting or forging molding. It is mainly made of hard materials such as steel through multiple processes, including thermal cutting, machining, heat treatment, wire cutting, polishing, butt welding, reinforcement, drilling and painting, etc., which ensures the wear resistance, durability and oxidation resistance of the mold. Unburned brick machine molds are usually made of steel, especially high carbon steel mold steel plates. The production process includes multiple processes such as thermal cutting, machining, heat treatment, wire cutting, polishing, butt welding, reinforcement, drilling, painting, etc. This mold has the characteristics of wear resistance, durability and oxidation resistance. The raw materials that can be used for unburned brick machine molds include mixtures of cement, sand, concrete, fly ash, slag, slag, tailings and construction waste. The mold needs to be cleaned and lubricated after use to extend its service life and maintain accuracy.