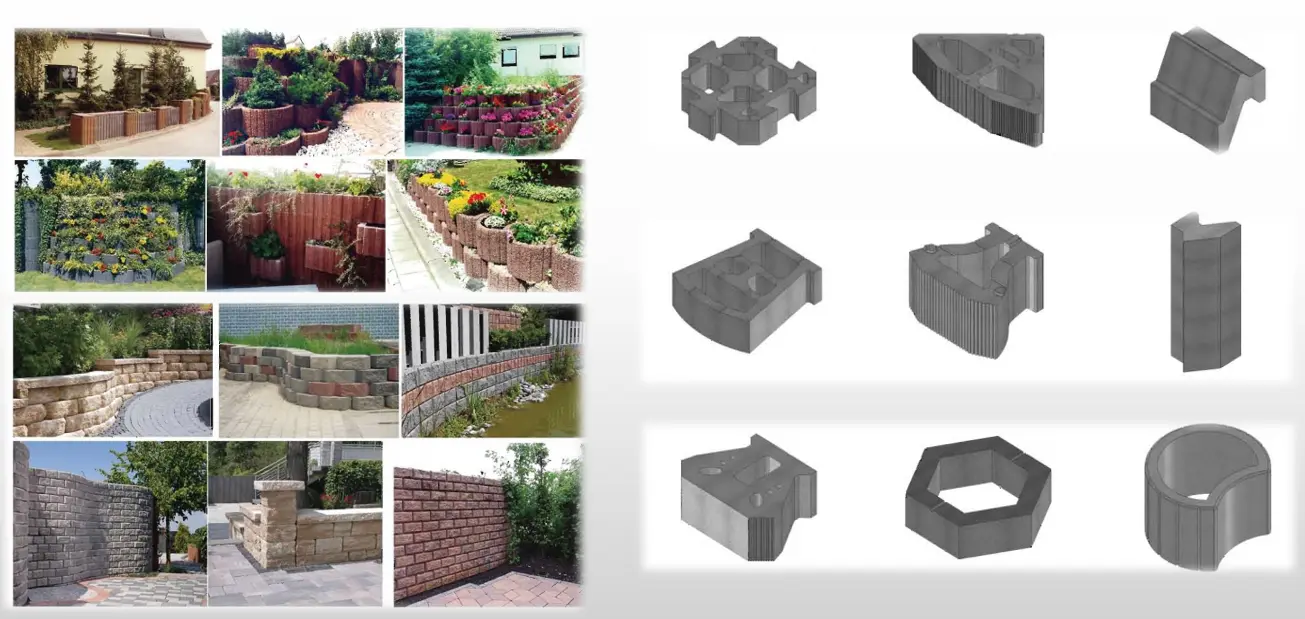

As a professional High-capacity Block Machine Mold manufacturer, you can rest assured to buy High-capacity Block Machine Mold from our factory and QGM Block Machine will offer you the best after-sale service and timely delivery.

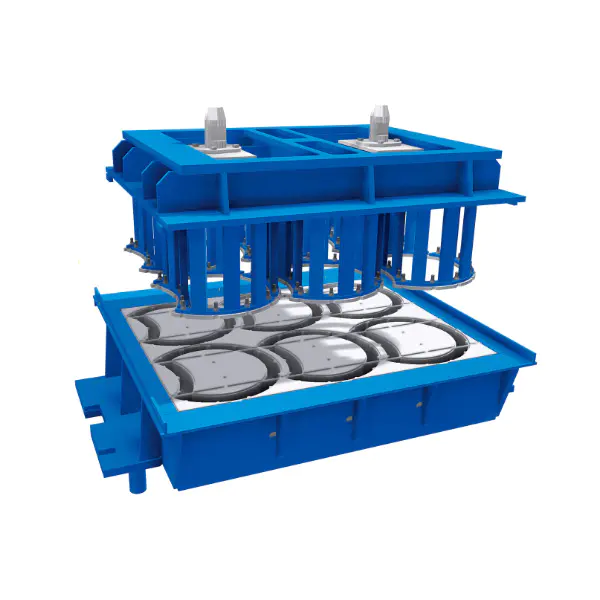

High-capacity block machine mold occupies a very important position in the entire brick machine equipment. The appearance, quality and production efficiency of the products produced play a decisive role in the whole set of equipment. Therefore, our block machine mold producers must choose to cooperate with manufacturers with strength and experience in whole set mold processing when purchasing molds. So as not to cause you unnecessary losses. Let's discuss the processing technology of block machine molds. First of all, we need to see what kind of block molds are made. What kind of block machine mold equipment is used. Then choose what kind of steel material to process. The material of steel determines the life of the unfired brick machine mold. Then treat it according to the material of steel. The treatment methods include carburizing, nitriding, carbonitriding, etc. The heat treatment method should be determined according to the steel material you choose. The next step is welding. According to the processing technology of the previous few parts, select suitable welding materials for welding. Pay attention to the deformation coefficient of steel during welding. Reduce deformation as much as possible, and then after all welding is completed, the upper and lower molds of the block forming machine mold are corrected. It is better if there is no friction between the upper and lower molds during correction, and the gap is generally controlled at 0.5-0.75 mm.