QGM Block Machine is one of professional China Industrial Grade Brick Moulds manufacturer and supplier, if you are looking for the Industrial Grade Brick Moulds with low price, consult us now!

Industrial grade brick moulds are key tools in brick production. Their design, manufacture and application are crucial to improving production efficiency and product quality. The following is detailed information about industrial grade brick moulds:

Features and advantages

High-quality materials: Made of high-quality alloy steel or special low-carbon alloy steel, it has the characteristics of wear resistance and high strength, ensuring the service life of the mould and the accurate size of the bricks produced.

Advanced technology: Advanced processing technology, such as carburizing, nitriding and other heat treatment methods, is used to improve the hardness and wear resistance of the mould.

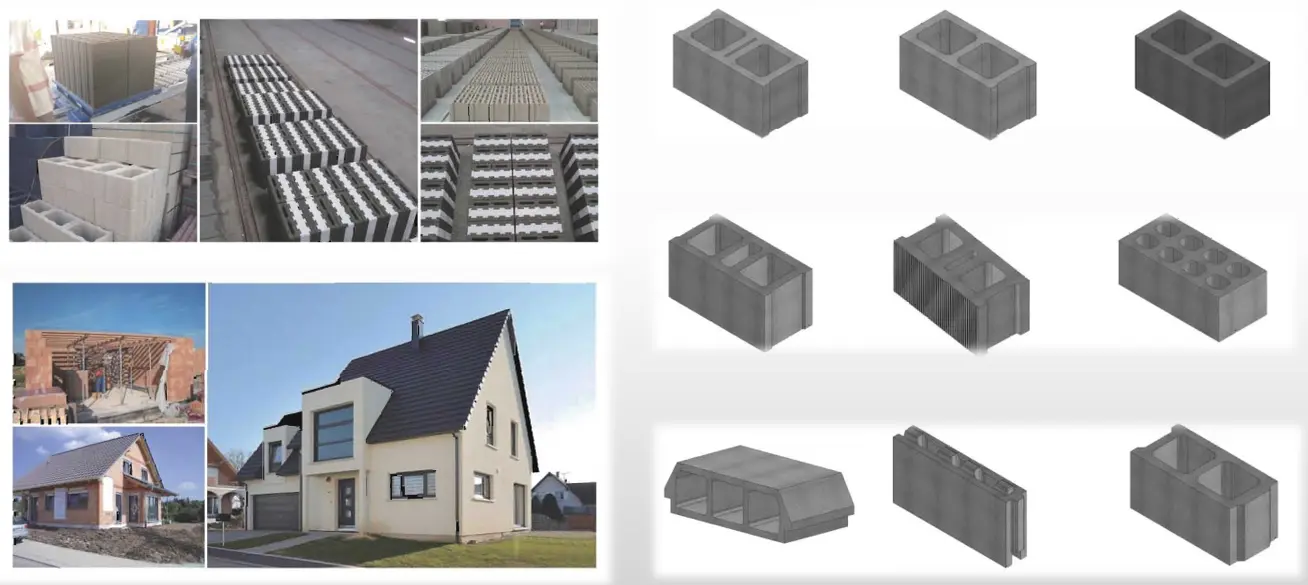

Customized service: The mould can be customized according to different production needs to meet diverse production requirements.

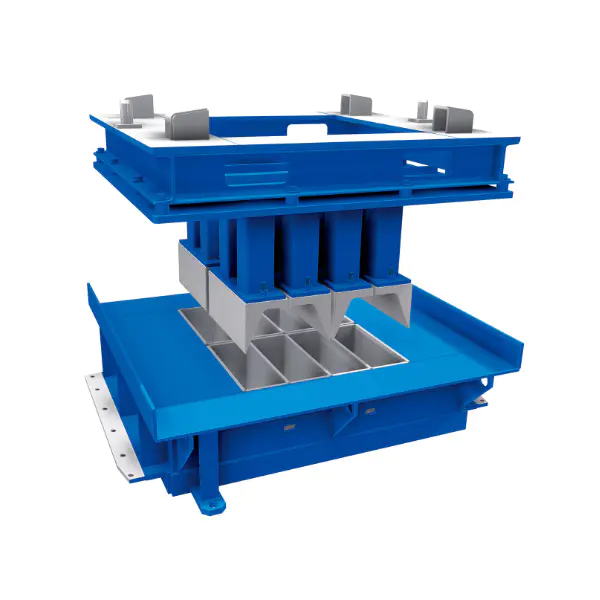

Structural design

Upper and lower mould structure: Common structures include upper mould and lower mould, the upper mould is provided with pouring holes, and the lower mould has a protruding base.

Special design: Some moulds are provided with rotatable side clamps on both sides of the upper mould, which are kept open by springs to prevent collision with the foam plastic board when closing the mould.

Function and application

Molding function: The mould plays a molding role in the production of blocks, by pouring concrete mixture and curing it.

Improve production efficiency: Highly automated molds can form multiple blocks at a time, improving production efficiency.

Maintenance and care

Daily inspection: Regularly check the mold size and welding parts, and repair cracks and wear in time.

Cleaning and storage: Use air compressors and soft tools to clean the molds, and apply oil to prevent rust and deformation when storing.

Choosing the right industrial-grade brick mold is essential for producing high-quality bricks. High-quality molds can not only improve production efficiency, but also reduce production costs.