QGM Block Machine is one of professional leader China Sustainable Building Moulds manufacturer with high quality and reasonable price. Welcome to contact us.

Sustainable building moulds are one of the key factors in achieving sustainable building goals. By selecting environmentally friendly materials and optimizing the design, these moulds can effectively reduce the impact on the environment while improving the efficiency and quality of construction.

Features:

Material selection: Sustainable building moulds usually use materials that have little impact on the environment and are easy to recycle and reuse. For example:

Mould steel: Although traditional mould steel is widely used, new environmentally friendly mould steels such as powder metallurgy steel and high nitrogen steel are gradually replacing it because of its better wear resistance and service life.

Aluminum alloy: Due to its lightweight and recyclability, it is often used to make large or small precision moulds.

Engineering plastics: Such as polyamide (PA), due to its corrosion resistance and low cost, it is widely used in injection moulds and other fields.

Design optimization: The design of sustainable building moulds focuses on improving resource and energy efficiency. For example:

PC building moulds can accurately control the amount of concrete and reduce material waste.

The diversity of design allows the mould to produce a variety of prefabricated components to meet different architectural styles and functional requirements.

Application scenarios:

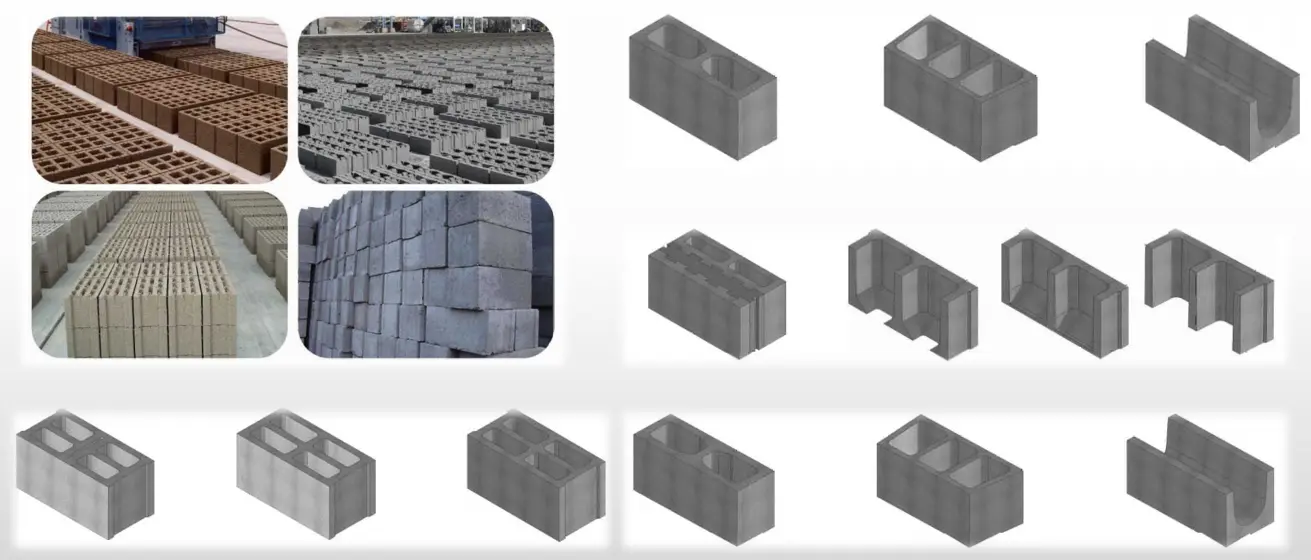

Precast concrete component production: Sustainable building moulds play an important role in the production of precast concrete components. For example:

High-precision PC building molds ensure the dimensional accuracy of prefabricated wall panels, stairs and other components, and improve assembly efficiency.

The molds have a high turnover rate, which reduces production costs.

Green building projects: In green building projects, the application of sustainable building molds helps achieve energy conservation and emission reduction goals. For example:

By optimizing mold design, the waste of concrete materials is reduced.

The quality of prefabricated components is stable, which reduces the damage rate during installation and further reduces material loss.